4 in 1

Four in one laser machine: Laser welding--weldseam cleaing--remote cleaning--laser cutting together

Five Laser company developed 4 in 1 handheld laser machine, it can do laser welding, weldseam cleaning, remote cleaning (rusty removal) together. It is suitable for welding stainless steel, carbon steel, titanium alloy, galvonized sheet, aluminum alloy. Especially for metal working factories, the 4-in-1 laser machine can do jobs in weldseam cleaning, laser welding, rusty removal before coating process. The laser power have 1000w, 1500w, 2000w & 3000w for optional

Ready-made laser welding process parameters

Just need to select the materials and thickness on process package, then the experienced process setting will come out. For example when you want to welding on aluminum alloy, just select "aluminum" items and select corresponding thickness, then you can weld the workpieces directly for saving your setting times

4-in-1 laser welding machine FAW-1000 (1000w) & FAW-1500 (1500w)

Compact design for 4-in-1 laser welding machine FAW-1000 (1000w) & FAW-1500 (1500w)

New 4-in-1 laser welding cabinet design for optional, commonly can be used for 1000w & 1500w

If need 2000w & 3000w, then the laser cabinet should be changed to larger one like the above red+white color cabinet. The FAW-2000 (2000W) & FAW-3000 (3000W) will be same above

Cleaning Welding Cutting

It's easy to shift from laser welding to laser cutting, only need to exchange the welding nozzle to cutting nozzle

If need to shift from laser welding/laser cutting to laser cleaning, then just need to exchange the focus lens insert tool & cleaning nozzle, then can do metal rust removal directly

Comparison

Different cleaning methods compare to laser cleaning methods

Laser cleaning technology have many advantages for rust removal such as faster cleaning speed, great cleaning affects, no extra cleaning pollution, precise controllable (easy integrated with automation & robot), no consumable required.

Comparison

Different welding methods compare to fiber laser welding

Comparison between argon arc welding & fiber laser welding

Comparison between YAG laser welding & CW fiber laser welding

Look at our laser welding speed

Faster speed means higher welding efficiency & lower labor cost

No professional welder? Never mind

Raytools welding control system plus 4-in-1 laser torch, which can exchanged functions on touch screen between laser welding, remote cleaning (rust removal), weldseam cleaning & handheld cutting

Even a new worker without welding experience, you can also do perfect welding by our laser, ecommonly it take one day learning will be enough for qualified welding effect.

Handheld cutting

Cutting on stainelss steel will be easy, you can cut a straight or curve line, or other shape you want

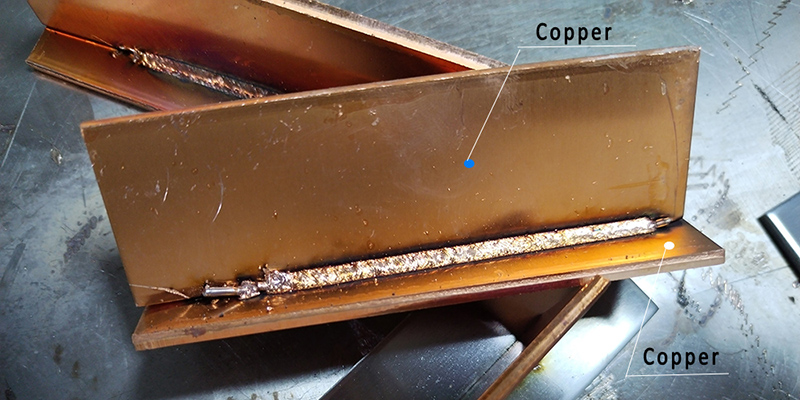

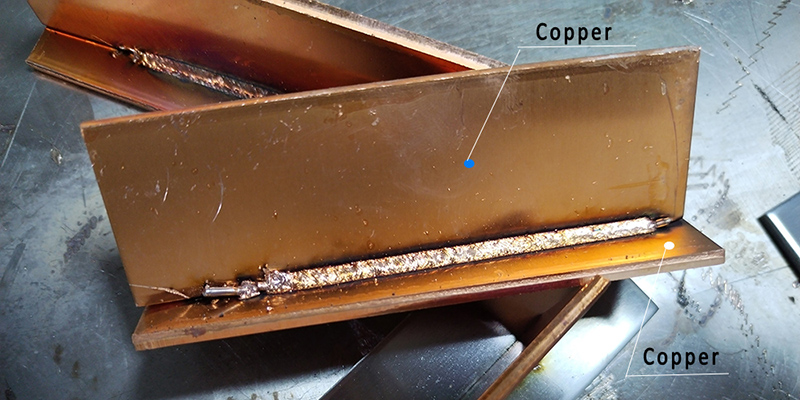

In the past the laser welder widely applied on stainless steel welding, carbon steel, aluminum alloy welding. Right now copper welding will be new application for laser welder, even different material welding together, for example copper welding with stainless steel together. Our company, Five Laser also got very good welding performance for different material welding.

Before or after welding, weldseam cleaning is popular application, which can improve the welding performance and surface quality, the weldseam cleaning width can reach 10mm

The details of laser head

(welding/cleaning/cutting torch)

Innovative Four-in-one laser head or called laser welding torch/laser cleaning torch/laser cutting torch. Light body design & insert-type protective lens design. No need to buy several laser machines for these different jobs, just need one set 4-in-1 laser system for welding, cleaning, cutting together

How to keep a laser machine in high quality and high stability?

Adopting famous raycus brand continuous fiber laser source as core to make sure high stability operation in long term. Also improved design in water cooling to make sure for exhausting complete heating from chiller fan. Better cooling termperature control makes machine working in more stability.

During laser welding or laser cutting, especially welding on high reflective materials such as aluminum alloy or carbon steel, there will be more splashes. The insert-type protective lens will be convenient for operator to exchange and daily maintenance, it can protect inside focus lens, reflective mirror & collimated lens max

The laser welding nozzle including normal welding nozzle & feeding welding nozzle. The normal welding nozzle is for internal/external corner joint welding, Tee joint welding & butt welding; The feeding welding nozzle is for welding with wire feeder; And cutting nozzle is for handheld metal cutting. According to materials the nozzle have brass nozzle and copper nozzle for optional, and copper nozzle have better heat dissipation performance than brass one. The nozzles we adopts is have advantage in less spatter than traditional one

Professional automatic wire feeder. The laser machine can do welding on materials directly without wire feeder, also it can working together with automatic wire feeder for stronger welding performance. The system have automatic feeding wire withdraw function while welding finish, which can make sure the feeding wire separate with welding materials smoothly

Four in one handheld laser welder

Models and specifications

FAW-1000 (1000w)-- welding 0.5~2.5mm stainless steel

FAW-1500 (1500w)-- welding 0.5~3.5mm stainless steel

FAW-2000 (2000w)-- welding 0.5~4.5mm stainless steel

FAW-3000 (3000w)-- welding 1.0~6.0mm stainless steel

Series: Handheld FAW series

Name : 4 in 1 laser welder

Welding width: 5mm max.

Welding head weight: 0.9KG only

Remote clean width: 80mm max

Weldseam clean width: 10mm max

Cutting function: Cutting by handheld

Laser source: Raycus laser source

Laser source option:JPT、Max

Cooling: Teyu S&A water chiller

Dispaly: 7" touch screen

Lauguage:English/Spanish/Russian...(more than 10 languages)

Blue/white cabinet dimension: 94*58*68cm (1000w & 1500w)

White/black cabinet dimension: 98*66*105cm (1000w & 1500w)

Red/white cabinet dimension: 116*66*121cm (1000w~3000w)

Input power: 220V+/- 10%, single phase for 1000w~2000w

Input power: 380V+/-10%, 3 phase for 3000w machine

Electrical frequency: 50Hz is as standard ( 60Hz is for optional)

info@fivelaser.com

info@fivelaser.com